How Manufacturing and Industrial Businesses Can Make the Most of Planned Downtime

Share Article

If you run a manufacturing or industrial business, you understand the one thing that can hurt you most: downtime. Downtime, especially when it pops up unannounced, is the express lane to business failure.

Just how badly downtime can cripple your business is the subject of much speculation, but experts generally agree that any downtime is bad, and the bigger the business the bigger the negative impact.

In an ideal world, manufacturing and industrial businesses would never have to deal with downtime. But, of course, that world does not exist.

Therefore, downtime is a fact of life for business owners. If there is a bright side, it is that sometimes downtime is planned, and when managed correctly planned downtime is not all that bad.

Planned downtime has the potential to deliver longer spans of uninterrupted operations for manufacturers, which can lead to success down the road. When executed strategically and effectively, planned downtime can dramatically reduce the likelihood of encountering the true killer in the business world: unplanned downtime.

Source: iStock

When Bad Things Happen to Good Businesses

A recent article in Forbes magazine suggests that 82% of manufacturing companies have experienced at least one unplanned downtime event over the past three years, with most companies experiencing two or more. Some folks attribute this fact to that famous axiom originally put forth by Edward Murphy, which states that anything that can go wrong will…at the worst possible moment.

Still, a cold evaluation of unplanned downtime events for manufacturing businesses seldom identifies completely unexpected, “out of the blue” failures or breakdowns. An honest appraisal normally points to one or more factors that could have been anticipated.

In other words, you can’t eat a jelly donut every morning for 10 years and act truly shocked when your doctor points out high cholesterol and triglyceride levels. You can fake it, but you know better.

The same logic applies to manufacturing businesses that depend on equipment and systems that keep them up and running. Regular maintenance and strategic repair and upgrade are the keys to long-term success.

Source: iStock

That is why successful businesses anticipate downtime and plan to make it as productive as possible. Successful businesses use downtime to their advantage. Successful businesses pick their service providers very carefully.

Capture the Upside of Downtime with FSG

When it’s time to upgrade your facility or perform needed maintenance, you need to find a service provider that understands your desire to minimize downtime. You need a project partner who shares your sense of urgency.

As it happens, FSG understands the situation. For over 40 years, FSG has been delivering lasting value to customers who all have one thing in common: they need to be up and running as soon as possible.

It doesn’t matter if the project involves new EV charging stations, parking lot lighting, office lighting, high bay warehouse lighting, electrical construction, electrical service, signage, building disinfection, or smart building controls, sensors, and networking. Every service we provide gets executed with a shared sense of how urgent the need to minimize downtime is for your business.

While this principle applies to every customer FSG serves, we believe it can be seen most dramatically on large projects, where the stakes are naturally higher, and where matters of logistics and planning make the difference between overall project success or failure.

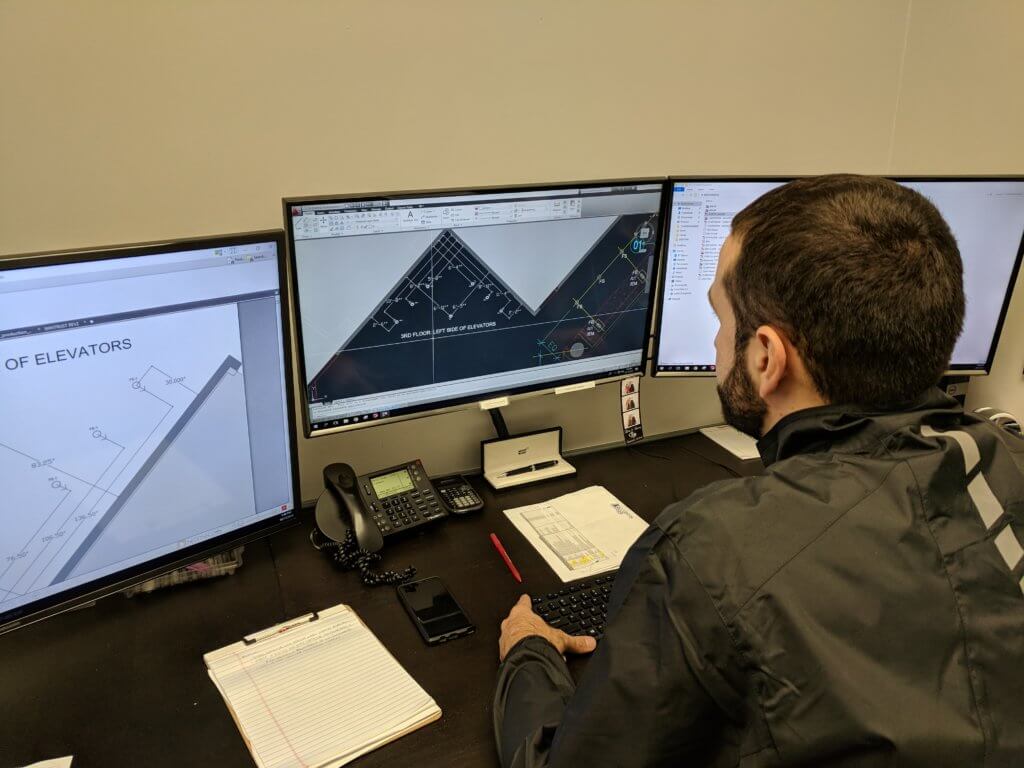

Source: FSG Media

Our experience with large-scale projects, coupled with our national product distribution network, delivers a winning solution for customers who have worked hard to anticipate and manage change and require an absolute minimum disruption to their normal operations.

For decades, those particular customers with those specific needs have turned to FSG.

FSG and the Art of Large-Scale Project Execution

When a project is required at a facility with several hundred thousand or maybe a million or more square feet of enclosed space, just wanting to do a good job is not enough. Plans must be made to execute the work within the normal flow of activities at the facility.

Within facilities of this size, operations typically take place on shifts, every day of the week. These businesses are focused on quotas and production goals, and interruptions must be both planned and brief.

The equipment, tools, and products associated with all work on projects at this scale must be shipped, stored, and utilized according to a project schedule that takes into account all variables of space, time, and available resources. To make this happen, clear communication and coordination are essential.

Most importantly, a service provider looking to execute a large-scale upgrade or retrofit project for a customer who operates a massive facility needs to understand that uptime is life and downtime is death for that customer. The project will never deliver lasting value if the act of completing it damages the business.

CLICK HERE TO READ FSG’s CASE STUDIES

Because FSG is an institution that has been built to deliver lasting value for our customers, understanding this fact might just be what we do best.

Project Support Across State Lines and Around the Clock

Back in 2015, FSG completed an LED retrofit project for a major auto manufacturer at facilities in three states, one of which measured 2.4 million square feet. For this project, FSG worked around employee shifts at each facility to limit downtime while observing strict safety and confidentiality requirements related to the customer’s manufacturing processes.

Due to our extensive experience working for numerous customers in similar situations, FSG was able to confidently submit a plan to the manufacturer outlining an expert and accurate LED installation that would align with each of their requirements. Most importantly to the customer, FSG’s LED retrofit project plan was structured to avoid disruptions to their normal operations.

The multi-site lighting retrofit was executed smoothly and quickly to the customer’s ultimate satisfaction. In all, 10,272 fixtures were replaced resulting in an annual 13,469,574 kilowatt reduction.

Source: FSG Media

Plan for Success with FSG

If you run a manufacturing business and you want to make the most of planned downtime, contact FSG today to talk to one of our professionals about your project. From lighting to electrical to building controls, we’ve got you covered with the very best products and technology to promote your success.

If your project involves the exterior of your business, such as parking lot lighting or new EV charging stations for your customers and employees, FSG can also make sure the work gets done in a way that avoids unnecessary business interruptions.

In the end, know this: FSG understands the importance you place on uninterrupted operations at your facility, and we are focused on delivering a project experience that you will value for years to come.

Contact us today or call (877) 293-6689 to find out how FSG can work for you.